What is a Kanban about?

As Kanban means “signboard” in Japanese, the Kanban method is a visual system for managing a production flow. Kanban was born in the 1950s at Toyota, in the automotive industry, and introduced in software development in the 2000s.

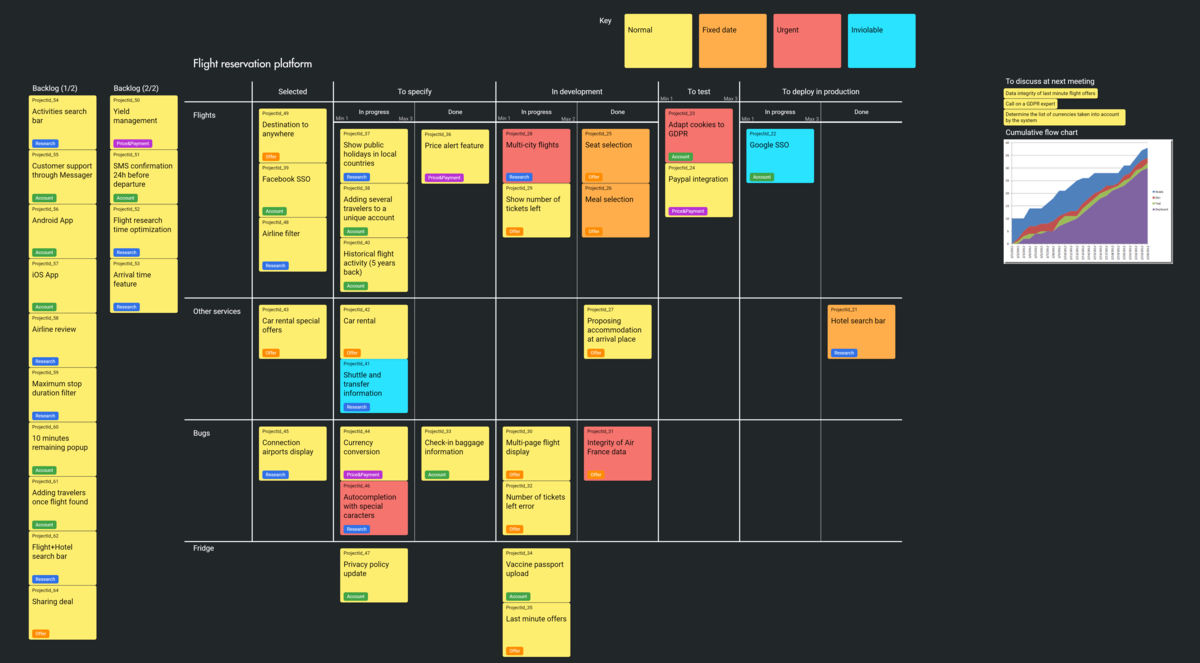

The Kanban card is a central component of the Kanban system. It represents a work item (or a task) and centralizes key information needed to realize it.

The primary purposes of the method are to allow all stakeholders to visualize the value creation process and share managing rules transparently. The Kanban Board represents the state of the production process at a given time, displays the managing rules, and enhances collaboration in teams.

The Kanban system encourages teams to limit work-in-progress to balance the workload across all process steps, according to their maximum capacity. Furthermore, it provides a framework for measuring the workflow, managing the workload, and promptly identifying potential frictions.

How to set up a Kanban system?

Delineate input and output interfaces

As a Kanban system represents the whole workflow of a given process, you should first identify accurately what this process encompasses as well as the upstream and downstream processes. The work items that are waiting to enter the process is generally called a backlog.

Define what is considered a work item

Here the challenge lies in determining the right granularity, i.e., the proper level of abstraction for supporting communication in the team and establishing a common language. You should define the size of work items with a view to streamline the demand and leave some room for dealing with possible changes, feedback, and urgencies.

Model the workflow

The workflow is a sequence of tasks and states that compose the process. To build it, you should map the process flow to describe the work done on the field by the people involved.

The Kanban Board should contain queues between each process step. They characterize items that can impact delays, but not teams’ productivity, like an expert opinion, validation from management, presentation to stakeholders, etc.).

Define the system rules

As part of Kanban, you should establish some rules at each process step. First, the rules to enter and exit the process. Then, internal rules describe what you should do when a work item is blocked too long, there is priority change, a work item is drained out of the process, or simply a work item passing from one step to the next.

How to set up the visual management system?

In the manual Kanban, L'approche en flux pour l’entreprise agile, Agile Coaches Laurent Morisseau and Pablo Pernot define visual management as “using visualization techniques to manage the workflow, make problems visible, and allow teams to react.”

Visual management is compelling for helping teams make the right decisions by making problems understandable and possible sticking points visible. To sum up, the authors state that the goal is to allow any team member to answer the following questions:

- How can I do my work correctly without having anyone telling me what to do?

- What is the next task to tackle?

- Do I have all the information I need for completing this task?

- Why am I stuck?

- How can my work impact progress, deadlines, quality, and team performance?

The Kanban card characterizes a work item and centralizes all data required for implementing it and managing its implementation. That being at least:

- Entry date in the process,

- Actual exit date to calculate the time to complete,

- Information needed to realize the work,

- Type of work item (task, research, infrastructure work, bug, etc.),

- Id to track the work item.

The Kanban Board shows the whole workflow. A column represents each operation, and lines break the work by type, team, priority. The board should also display the rules, for instance, the maximum capacity per column, and expose the roadblocks.